Generally, a complete small scale cooking oil processing machine is made up of cleaning machine, cooker, cooking oil press machine, oil filter machine, cooking oil refining machine and more. But, all the equipment should be choose based on the properties and pressing process of your raw materials. For example, if you are going to set up a peanut oil pressing line, the peanut sheller is necessary to remove the outer shell of peanuts. If there are any questions about setting up a small oil press production line, please let us know!

|

| Small scale cooking oil processing machine |

The working principle of small scale edible oil etraction machine is to separate vegetable oils directly from the raw materials by physical pressure. The whole process is without any chemical additives, so as to ensure the safety, sanitation natural nutrition of oil. And the process is free from pollution. The merits of the pressing technology is that it requires less equipment, has good adaptability to different raw materials, allows flexible production, ensures best quality, color and flavor of oils.

|

| Small scale peanut oil processing machine |

Hot products

Peanut oil processing machine

soybean oil processing machine

sunflower oil processing machine

Contact information:

http://www.cookingoilmillmachinery.com

http://www.edibleoilextractionmachine.com

'whatsApp/wechat: 0086 13526627860

E-mail: oilmachine@doinggroup.com

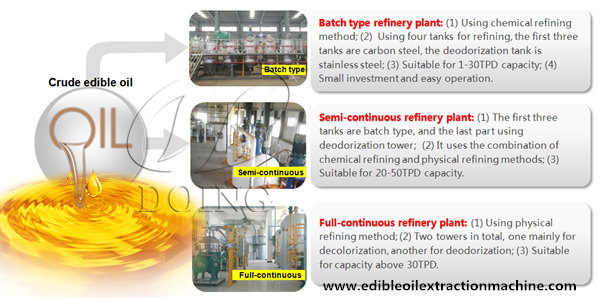

Different types peanut oil refining machine

Different types peanut oil refining machine 1-10tpd batch type peanut oil refining machine

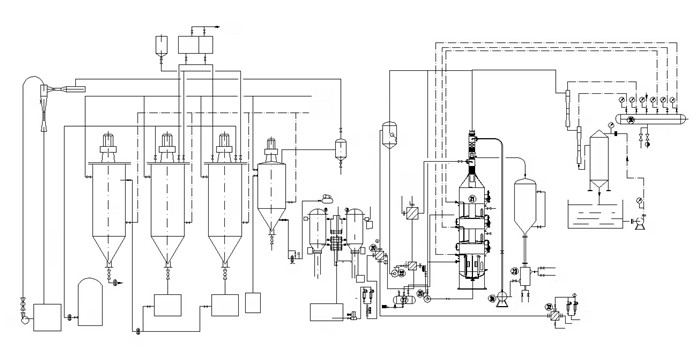

1-10tpd batch type peanut oil refining machine 1-10tpd batch type peanut oil refining process flowchart

1-10tpd batch type peanut oil refining process flowchart Soybean oil extraction machine

Soybean oil extraction machine Single screw soybean oil press machine

Single screw soybean oil press machine Integrated soybean oil press machine with filter

Integrated soybean oil press machine with filter Soybean oil solvent extraction plant

Soybean oil solvent extraction plant